Fixing to formwork

Sika Waterbar® O VN may also be used to in conjunction with split formwork. However care should be taken to ensure that the “O” ring is not squashed flat between two forms. This method of installation increases the capacity of the Sika Waterbar® O VN to accommodate expansion.

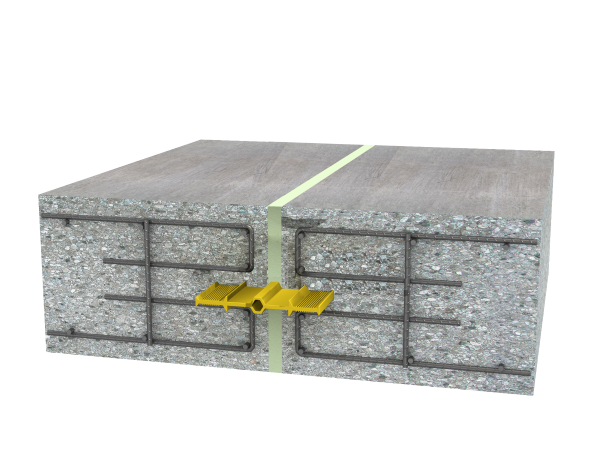

Fixing Reinforcement

Pre-punched eyelets are located in the outer flanges of the profiles. These simplify the fixing of waterbars to the steel reinforcement with tie wires to ensure the waterbars are not displaced during concreting.

Placing concrete first stage

Sika Waterbar® O VN performs its function only if both sides are well embedded in the concrete. Avoid formation of honey combs by vibrating carefully.

The consistency of the concrete itself should be neither too plastic nor too stiff, and the aggregate must be well graded.

Placing of fresh concrete near the Sika Waterbar® O VN requires care, as otherwise it will be forced from its position by the pressure of the fresh concrete, i.e. the ends will fold up. To prevent this, the same concrete pressure must be present on both sides of the Sika Waterbar® O VN.

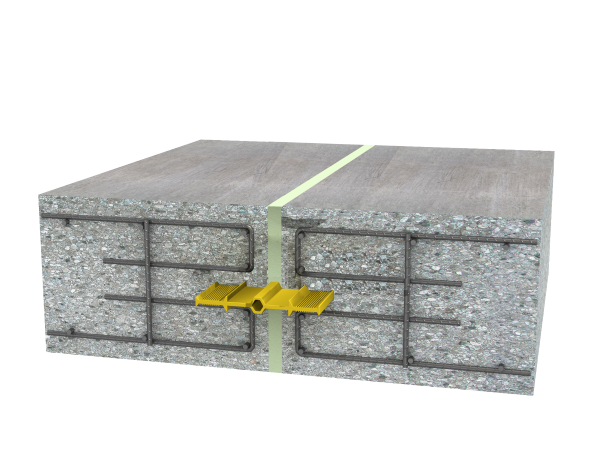

Placing concrete second stage

Removal of formwork in the neighborhood of Sika Waterbar® O VN must be done with care.

The end of the Sika Waterbar® O VN should be thoroughly checked for honey-combing on the stop-end and repaired if necessary. It must also be cleaned of all hardened concrete remnants adhering from the first concrete stage. Further procedure is similar to the first stage.

Welding

On site welding can be undertaken using a electric welding knife. Both ends of the joint are heated simultaneously on the faces of the welding knife until an even, molten bead of PVC appears. The welding knife is withdrawn and the Sika Waterbar® O VN are immediately pushed together. The joint should be held rigid until the plastic cools down and solidifies.

Check for any gaps or imperfect joints.

Failures can be caused by irregularities of cut edges, insufficient heat, dust etc.