Sikafloor® DecoDur ES-26 Flake

Sikafloor® DecoDur ES-26 Flake is a decorative, coloured, smooth low VOC, full flaked floor covering designed for indoor applications.

- Decorative

- Low VOC-content

- Good mechanical and abrasion resistance

- Easy application

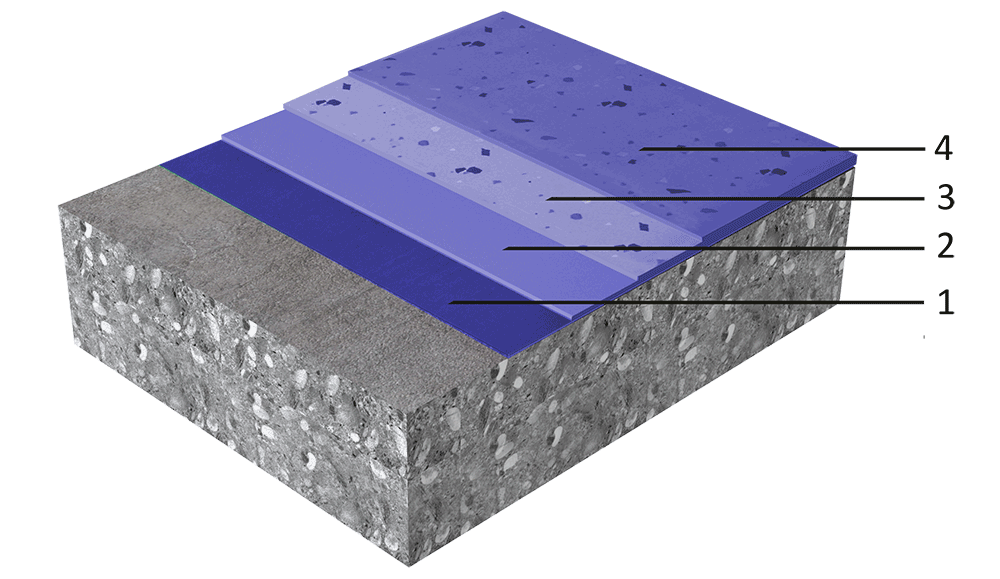

System Structure

1

Primer

2

Primer/Seal coat

3

Wearing coat

Usage

- Particularly used in the life science, pharmaceutical industries and health care industry

- Education (e.g. Schools and Universities)

- Leisure & Culture (e.g. Museums, Stadiums)

- Retail (e.g. Shopping Malls)

Advantages

- Decorative

- Low VOC-content

- Good mechanical and abrasion resistance

- Easy application

Packaging

Please refer to the individual Product Data Sheets

Colour

| Iceberg:

| Hiero:

|

| Noblesse:

| Amand:

|

| Framboise:

| Fleur de Tilleul:

|

| Blue Jean:

| Nougat:

|

| Mer du Nord:

| Bordeaux:

|

| Granit:

| Peche:

|

| Dune:

| Sanguine:

|

| Sable:

|

Appearance

Glossy orange peel finish possible

System Details

APPROVALS / STANDARDS

- Particle emission certificate Sikafloor® DecoDur ES-26 Flake CSM Statement of Qualification Report GMP A- No. SI 1008-533 (system tested with Sikafloor®-169 as a top coat)

- Biological resistance certificate Sikafloor® DecoDur ES-26 Flake CSM Statement of Qualification – ISO 846, very good - Report No. SI 1008-533. (system tested with Sikafloor®-169 as a top coat)

System Structure

Sikafloor® DecoDur ES-26 Flake system

| Layer | Product |

| 1. Primer | Sikafloor®-156, -160, -161 or -169 |

| 2. Wearing coat | Sikafloor®-263 SL or -264 pigmented approx. the same like the following Sika PVA ColorFlakes (filled 1:1 with quartz sand 0.1–0.3 mm) |

| 3. Broadcast & Seal coat | broadcast in excess with Sika®-PVA ColorFlakes 3 mm First seal coat with Sikafloor®-169. Soft grinding the next day and a second seal coat with Sikafloor®-169 |

| 4. Top coat | Sikafloor®-315 with high scratch resistance |

Composition

Epoxy

Nominal Thickness

~ 2–3mm

Shelf Life

Please refer to the individual Product Data Sheets

Storage Conditions

Please refer to the individual Product Data Sheets

Reaction to Fire

Bfl-S1 | (DIN EN 13501-1) |

Chemical Resistance

Resistant to many chemicals. Conact Sika technical service for specific information.

Skid / Slip Resistance

| R9 | (DIN 51130) |

Application

Product Temperature

Please refer to the individual Product Data Sheets

Ambient Air Temperature

+10 °C min. / +30 °C max.

Relative Air Humidity

80 % r.h. max.

Dew Point

Beware of condensation! The substrate and uncured floor must be at least 3°C above dew point to reduce the risk of condensation or blooming on the floor finish.

Substrate Temperature

When performing application work with Sikafloor® Decodur ES-26 Flake, the substrate moisture content must not exceed 4 % pbw measured by Tramex.Test method: Sika®-Tramex meter, CM - measurement or Oven-dry-method.No rising moisture according to ASTM (Polyethylene-sheet).

Substrate Moisture Content

When performing application work with Sikafloor® DecoDur ES-26 Flake, the substrate moisture content must not exceed 4 % pbw measured by Tramex.Test method: Sika®-Tramex meter, CM - measurement or Oven-dry-method.No rising moisture according to ASTM (Polyethylene-sheet).

Waiting Time / Overcoating

Before applying Sikafloor®-169 on Sikafloor®-156/ -161/ -160/ -264/-169 allow:

| Substrate temperature | Minimum | Maximum |

| +10 °C | 36 hours | 4 days |

| +20 °C | 12 hours | 2 days |

| +30 °C | 8 hours | 1 day |

Before applying Sikafloor®-315 on Sikafloor®-169 allow:

Before applying Sikafloor®-315 on Sikafloor® epoxies, the surface has to be treated with a green Scotch-Brite™ pad to remove contaminations or be cleaned professionally with Kärcher RM 776 or Veroclean.

| Substrate temperature | Minimum | Maximum |

| +10 °C | 30 hours | 4 days |

| +20 °C | 24 hours | 3 days |

| +30 °C | 6 hours | 2 days |

Times are approximate and will be affected by changing ambient conditions particularly temperature and relative humidity.

Applied Product Ready for Use

Sikafloor®-169

| Temperature | Foot traffic | Light traffic | Full cure |

| +10 °C | ~ 48 hours | ~ 6 days | ~ 10 days |

| +20 °C | ~ 30 hours | ~ 4 days | ~ 7 days |

| +30 °C | ~ 20 hours | ~ 3 days | ~ 5 days |

Sikafloor®-315

| Temperature | Foot traffic | Light traffic | Full cure |

| +10 °C | ~ 20 hours | ~ 48 hours | ~ 6 days |

| +20 °C | ~ 16 hours | ~ 36 hours | ~ 4 days |

| +30 °C | ~ 12 hours | ~ 24 hours | ~ 3 days |

Consumption

Sikafloor® DecoDur ES-26 Flake system

| Coating System | Product | Consumption |

| Primer | 1–2 × Sikafloor®-156, -160, -161 or -169 | 1–2 × ~ 0.3–0.5 kg/m² |

| Wearing coat | Sikafloor®-263 SL or -264 pigmented approx. the same like the following flake mix , filled 1:1 with quartz sand 0.1–0.3 mm | ~ 1.9 kg/m2 per mm |

| Broadcast | Broadcast in excess with Sika®-PVA ColorFlakes 3 mm | I~ 1.0 kg/m2 |

| First seal coat | 1 × Sikafloor®-169 | ~ 0.6–0.7 kg/m2 |

| Second seal coat | 1 × Sikafloor®-169 after sanding of the sealed surface | ~ 0.3 kg/m2 |

| Top coat (Optional) | 1 × Sikafloor®-315 after sanding of the sealed surface | ~ 0.128 kg/m² |

* Before applying Sikafloor®-315 please refer to the individual product data sheet.

CLEANING

Please refer to the Method Statement Sikafloor®‐ Cleaning Regime